-

28 Nov’ 2025

What are the differences in the roles of screw bars in injection molding and extrusion?

1. Functional Differences: The Screw Barrel in an injection molding machine is primarily responsible for forcing the melt into the mold and maintaining a seal under high pressure for rapid molding; wh...

-

21 Nov’ 2025

How does the choice of screw barrel material affect different plastics?

1. Matching Abrasion Resistance to Plastic Viscosity: Different plastics have significantly different viscosities and abrasive properties. High-viscosity polycarbonate (PC) or glass fiber reinforced m...

-

14 Nov’ 2025

How to perform daily maintenance and replace worn parts on a Parallel Twin Screw Barrel?

Daily Maintenance Points 1. Clean the unit surfaceAfter each shift, promptly clean the dust and residue from the Parallel Twin Screw Barrel's outer casing, hopper, and conveyor inlet to prevent buildu...

-

07 Nov’ 2025

What is the process of customizing a Rubber Screw Barrel?

1. Requirement communication and technical solutionThe customer provides process parameters such as rubber type, production capacity, and temperature range. The manufacturer formulates a technical sol...

-

31 Oct’ 2025

How do the threads inside the single screw barrel help with the melting and conveying of plastics?

1. High-precision machining and wear-resistant materialsAdvanced CNC machining centers and precision measurement technologies are used to ensure that the inner wall of the barrel is smooth and defect-...

-

24 Oct’ 2025

What are the temperature control methods for single screw extruders?

Temperature Control Methods for Single Screw Extruders 1. Thermocouple + Temperature Controller: Thermocouples measure temperature, and a digital temperature controller (PID) adjusts the heater for pr...

-

17 Oct’ 2025

What are the top ten common faults in single-screw extruders?

Ten Common Faults of Single Screw Extruders 1. The main motor fails to start or stops momentarily: This is often caused by a power outage, insufficient preheating time, or heater failure, resulting in...

-

10 Oct’ 2025

How does the thermal conductivity of a bimetallic screw affect product quality?

The Impact of a Bimetallic Screw's Thermal Conductivity on Product Quality 1. Improved Plasticizing Uniformity By creating radial convection within the screw channel, a bimetallic screw rapidly transf...

-

03 Oct’ 2025

Does the inside of the rubber screw barrel need to be heated or cooled?

Necessity of Heating1. Achieve Rubber PlasticizationBy heating the barrel wall, the rubber rapidly softens and melts under the screw's action, forming a uniform plasticized rubber compound.2. Ensure T...

-

26 Sep’ 2025

What are the key technical points of a single screw barrel in food?packaging film production?

Key technical points for using a single screw barrel in food?packaging film production1.Material Compatibility and HygieneUse food?grade alloy steel or stainless steel (e.g., 304, 316) that meets food...

-

19 Sep’ 2025

What are the main application scenarios of a rubber screw barrel?

Main Application Scenarios of Rubber?Screw?Barrel1.Rubber extrusion and molding Continuous extrusion of basic rubber products such as tire treads, inner tubes, rubber strips, hoses, and tapes.Producti...

-

12 Sep’ 2025

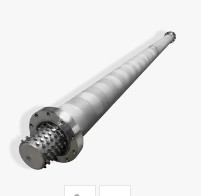

What is the core role of a single screw barrel in a plastic extruder?

1.Structure and Flow ControlThe Single Screw Barrel is manufactured with precision CNC machining centers and high?accuracy measurement technology, guaranteeing a smooth, defect?free inner wall. This a...

English

English 中文簡體

中文簡體

浙公網(wǎng)安備33090202000520號

浙公網(wǎng)安備33090202000520號